-

Contactez-nous

Contactez-nous

La découpe précise de vos montures, la place pour un changeur d'outils, et la fabrication française!

Votre besoin est unique, nous le prenons en compte. Contactez nous!

Ainsi nous étudierons l'ensemble de vos critères pour vous proposer la meilleure solution.

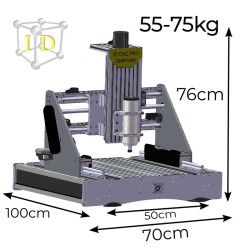

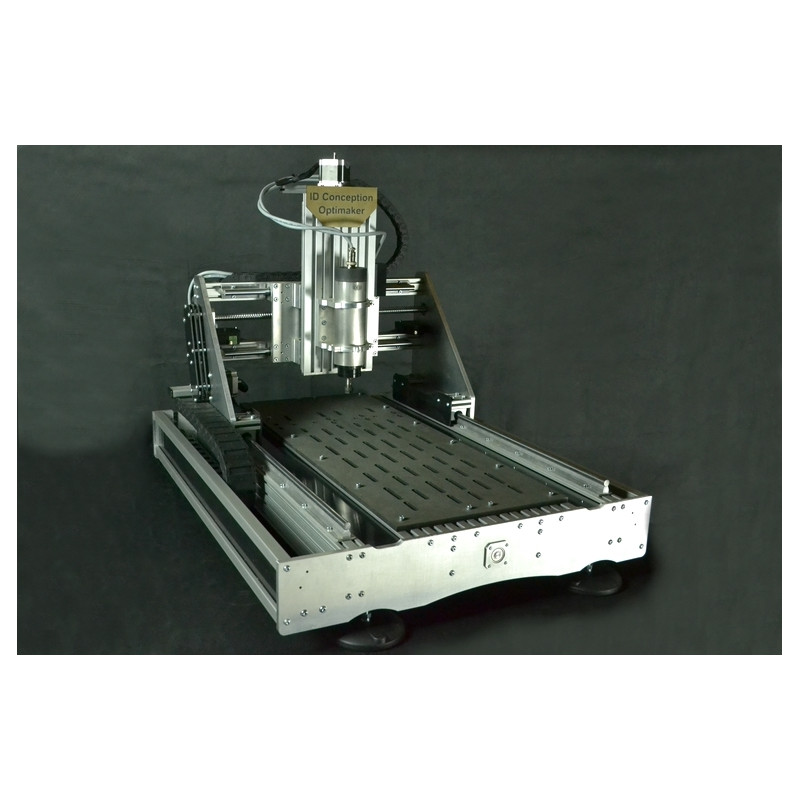

Extended version of the ID CNC Optimaker milling machine.

This milling machine, created, manufactured and tested in our workshop, specially sized for use in eyewear, has the same technology as the ID CNC Pro machines but in mannequin size in order to guarantee a perfect quality / performance / price ratio.

Thanks to this machine, you can unforce your frames, drill and embed the hinges, engrave and cut out faces and temples. You can also make inlays or other decorations at your leisure on the front face of sides and branches thanks to its turning module specially designed to guarantee perfect repositioning without adjustment on the cutting area.

This milling machine offers a machinable surface of 220x 500mm, with optional full protection cover to limit noise, chip dispersion and increase safety (compulsory for use in sales areas or in schools).

It is delivered as standard with a tool probe, Cambam and Mach3 software, a set of tools for getting started, a maintenance and use kit as well as a module for turning a frame (face and temples ) and its plate drilling system:

Like all available milling machines, it allows you to perform various machining, drilling, engraving, contour, 3D, etc. jobs in materials such as:

Matières naturelles :

cardboard, wood (soft and hard: from balsa to ironwood), horn, mother-of-pearl, ivory, etc.

Plastic materials :

Cellulose acetate, PMMA (Plexiglas), extruded and expanded PVC, polystyrenes, polycarbonate, ABS ...

Composites :

Carbon fiber, dibond, fiberglass, ...

Non-ferrous metals :

Aluminum, copper, brass, bronze, silver, gold.

Its entirely aluminum structure gives it flawless stability over time.

Its maintenance consists mainly of cleaning and greasing, simplified to the extreme thanks to its 3 grease nipples.

For ease of use, it is specially designed to harmonize with the French eyewear software OLGA / DXF to Gcode

It can be fitted with a protective casing

- Designed, manufactured and tested in our workshop in France

- Warranty for 2 years parts and labor

Delivered with:

- Universal wooden martyr + universal clamps

- Standard turning module 1 frame and its drilling jig

- 1 set of tools for drilling, milling and engraving

- 1 maintenance and use kit

- Cambam and Mach3 software suite

- 1 half-day including software installation of the machine and training in its use.

- Can be mounted with an automatic tool changer spindle of 5 tools

- Can be fitted with a protective casing

Accessories

-

Contactez-nous

Carter pour ID CNC Optimaker longue

Carter de protection pour ID CNC Optimaker longue

-

Contactez-nous

Changeur d'outils pour ID CNC Optimaker longue

Automatic tool changer (4 tools) for the long ID CNC Optimaker

This will increase your production rate, but above all your comfort of use by not having to wait for the machine to ask for a tool change during its use.